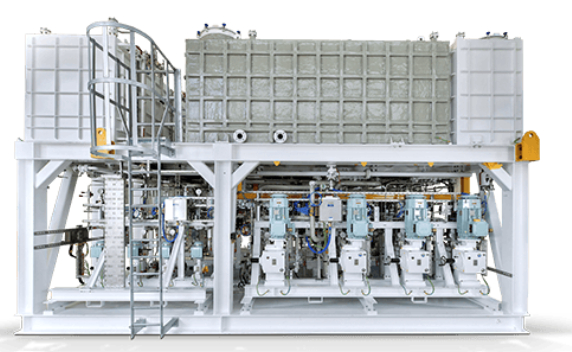

Chemical Metering & Injection system

A Chemical Injection & Metering Skid is a fully integrated system designed to inject and precisely meter chemicals into process streams at controlled flow rates and pressures. These systems are critical in oil & gas, FPSO units, refineries, petrochemical plants, and water treatment facilities.

Chemical injection and metering skids (CIMS) are critical for precise dosing of chemicals (e.g., corrosion inhibitors, scale inhibitors, biocides, demulsifiers) in offshore oil & gas production. Compliance with international standards, hazardous area certifications, and classification society rules is mandatory for safety, reliability, and regulatory approval.

Core Components

- Chemical Storage Tanks (SS316L, duplex steel, or HDPE)

- Metering Pumps (Diaphragm, piston, or peristaltic) – Must meet API 675

- Flow Meters (Coriolis, magnetic, or ultrasonic) – ISO 5167 / API MPMS

- Control System (PLC/SCADA with SIL 2/3 for critical functions)

- Pressure Relief Valves (ASME Sec VIII / API 520/521)

- Strainers & Filters (To ISO 2941/API 598)

Material Selection

- Carbon Steel (CS) with internal coatings (e.g., epoxy, PTFE)

- Stainless Steel (SS316L, 904L, Duplex 2205) for corrosive chemicals

- HDPE/PTFE Lining for aggressive fluids (e.g., HCl, H₂S)

Key Standards & Certifications Classification Society Approvals (Mandatory for Offshore)

- ABS (American Bureau of Shipping)

- DNV (Det Norske Veritas)

- Lloyd’s Register (LR)

- Bureau Veritas (BV)

- ClassNK

- RINA

Industry-Specific Requirements

- FPSO (Floating Production Storage & Offloading)

- DNV-OS-E201 (Process system reliability)

- IMO FSS Code (Fire safety systems)

- MARPOL Annex I (Oil Pollution Prevention)

- Offshore Platforms (Fixed & Floating)

- API RP 14J (Hazard analysis for offshore facilities)

- ISO 13702 (Fire & explosion protection)

International General Design & Safety Standards

- API RP 14C (Analysis of Safety Systems for Offshore Production Platforms)

- API RP 14E (Design & Installation of Offshore Production Piping Systems)

- ISO 10418 (Safety & Shutdown Systems for Offshore Platforms)

- ISO 13703 (Piping Design for Offshore Installations)

- ASME B31.3 (Process Piping Code)

International Electrical & Hazardous Area Compliance

- IEC 60079 (ATEX/IECEx) – Explosive atmospheres (Zone 1/Zone 2)

- IEC 60079-0 (General Requirements)

- IEC 60079-7 (Increased Safety “e”)

- IEC 60079-11 (Intrinsic Safety “i”)

- NFPA 70 (NEC) / NEC 500-506 (US Hazardous Location Standards)

- DNV-RP-A203 (Qualification of New Technology for Offshore Use)

International Materials & Corrosion Resistance

- NACE MR0175/ISO 15156 (Materials for H2S Service – Sour Environments)

- NORSOK M-001 (Materials Selection for Offshore)

- ASTM A106/A333 (Piping Material Standards)

International Functional Safety & Control Systems

- IEC 61508 / IEC 61511 (Functional Safety for Safety Instrumented Systems)

- SIL Rating (SIL 2/SIL 3) for critical shutdown systems

Typical Applications

Oil & Gas:

- Corrosion inhibitors

- Scale inhibitors

- Demulsifiers

- Hydrate inhibitors

Water Treatment:

- pH adjustment

- Disinfection (chlorine, ozone)

- Coagulants and flocculants

Petrochemical & Refineries:

- Catalyst dosing

- Anti-foam agents

Testing & Inspection Requirements

TEST

Hydrostatic Test |

Pneumatic Test |

Functional Safety Test |

Hazardous Area Inspection |

Vibration/Shock Test |

Salt Spray Test |

STANDARD

ASME B31.3 / API 598 |

ASME Sec VIII |

IEC 61508 |

IECEx/ATEX |

DNV/ABS/IEC 60068 |

ISO 9227 |

PURPOSE

Checks piping integrity |

Verifies leak-tightness |

Validates SIL performance |

Ensures Ex-proof compliance |

Simulates offshore conditions |

Corrosion resistance validation |